Meeting Projected Electricity Demands After Wasted Years of Pursuing Green Energy Isn't Going to Be Easy - Not at All!

Guest Post from Dick Storm.

Before I go any further, please know that I support President Trump and his policies to return manufacturing to America. Ever since NAFTA in the 1990’s, America has hemorrhaged manufacturing capacity. I presented my views on the harm of China entering the WTO in a 2016 presentation to the Delaware County Bar Association (PA) and also in personal observations made in Stanly County, North Carolina during the 1990’s. See here and here.

U.S. Climate policies begun during the Obama administration have destroyed over half of the U.S. dispatchable, reliable and affordable coal power generation fleet. I wrote an article on, “How the War on Carbon weakens America and strengthens China” in 2021. This is a self-Inflicted electricity generation crisis. The Obama and NGO “War on Coal” killed about 125,000 MW of coal plant generation capacity, and even more egregiously, the supply-chain to manufacture them.

So, what do we do now? (Hint: do as the Chinese are doing, read to the bottom)

The Challenge: Build 150,000 MW of new natural gas, nuclear and coal power generation by 2030 and 800,000 MW of new electricity generation capacity by 2050.

According to the global consulting firm ICF:

U.S. electricity demand is expected to grow 25% by 2030 and 78% by 2050.

U.S. peak electricity demand is expected to grow 14% by 2030 and 54% through 2050.

Residential retail rates could increase between 15% and 40% by 2030, depending on the local market.

The graph depicting electricity demand to 2050 below is from the ICF Report, May 2025. Notice they show coal power disappearing by 2040. THe 78% growth by 2050 is adding 1,014,000 MW to the current 1,300,000 MW of currently installed generation capacity. The 1,300 GW number is from America’s Public Power.

I tend to agree with the ICF load growth forecast but not on the exit of coal.

I believe the enormous generation growth from wind, solar, hydrogen, battery and geothermal is wishful thinking, a fantasy that many bureaucrats, politicians, and sadly, state policymakers and “woke” utility execs seem to believe.

Plans to exit coal are neither prudent nor realistic. They represent a self-Inflicted limit to economic growth, and if continued, will cause electricity rationing.

Dave Walsh and I participated in a panel discussion at Liberty University’s CEO Summit in September, 2024. The title of the panel was “Impacts of the Self-Inflicted Electricity Generation Crisis.” We laid out our views of the destruction of reliable, affordable, dispatchable power generation that was being destroyed by so-called, “Climate Policies.” This loss of reliable generation capacity without replacement in-kind has created a future electricity generation crisis. Two previous articles cover the facts and information of our presentations at Liberty University, here and here.

Shortages and Rationing of Electricity

Rationing is referred to by utilities, ICF, other recognized consultants, and bureaucrats as “Demand Response.” It simply means electricity will be rationed for charging your EV or running your air conditioner at the whim of your electricity provider. Why? because no utility or IPP is accountable for planning future generation as vertically integrated regional utilities once were (e.g., the old Duke Power of the 1970’s, Philadelphia Electric, Santee-Cooper and hundreds more). Worse yet, unreliable, intermittent solar and wind has been forced onto the grid with tax subsidies, thus weakening Grid reliability when power is needed at peak periods.

Demand Response sounds less threatening to the public than “Rationing.” Unfortunately, the path forward adopted by many (most) utilities is a path of shortages and rationing, by intention. Remember the old phrase? “Failing to plan is planning for failure?”

Power for the U.S.A

Power for the U.S.A. was the title of Donn Dears’ website, and I find it useful here. Dears’ last book “Clean Energy Crisis” offered Donn’s calculations of what he forecasted as being needed by 2050 if all electricity was to be generated by carbon-free sources. Here is what he calculated in 2023, before the AI demand became so well publicized:

881 new nuclear plants equivalent to Plant Vogtle’s last two units, each about 1,100 MW.

3,918,996 MW of new solar plus BESS (Battery Electric Storage Systems to back it up at night).

995,141 wind turbines of 2.5 MW each.

In conclusion, Mr. Dears stated this was unachievable. I believe that building 881 new nuclear plants by 2050 is unrealistic. Many others who are experienced in power generation share these concerns of supply chain weakness.

Ron Stein and I coauthored an article on a path forward with conventional forms of electricity generation, see here. Let’s expand that discussion to show the challenge of building 150,000 MW of new coal electricity generation plants and 400,000 MW of new nuclear plants. It is a given that by 2050, gas turbine powered generating plants can be built to make up the difference, but not ALL. Keep in mind, some forecasts predict that over 1,000 GW of new 24/7 electricity generation will be required by 2050. Therefore, the new capacity discussed herein is very conservative.

The Supply Chain for 125,000-150,000 MW of New Coal Power Generation

America had the manufacturing capacity in 2008 to build 150,000 MW of new coal plants. In fact, over 150 new plants were well along in the planning stages then, before the Obama carbon mandate killed them.

Energy and electricity are the Economy. Electricity has been the lifeblood of the economy of any developed or developing nation for over 100 years. To not plan for adequate primary energy and electricity generation for the future is to be un-American or even anti-American. Let’s get into what I suggest.

Examples of Manufacturing Capacity that Need to be Replaced

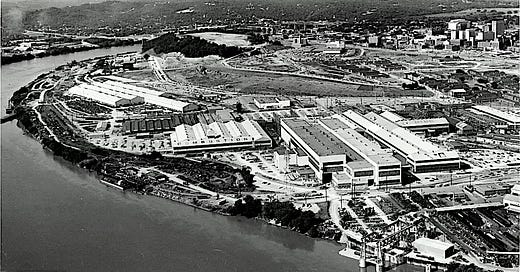

Somehow….America needs capital investment in similar facilities to the Combustion-Engineering’s Chattanooga works had in 1975. This needs to be started ASAP. Here is an aerial picture of this magnificent facility when it was in operation.

The facility was over 88 acres under roof and included capabilities for manufacturing steel tubing, waterwalls, heavy-walled headers, fabrication of tube assemblies as described above for the Roxboro superheater, and also nuclear reactors and steam generators. I intentionally used the adjective magnificent to describe it. Here is a quote from my friend Tom who worked at C-E during this time period:

“I did a stint at CE in Chattanooga and still vividly recall the enormity of the manufacturing capability. For instance, 15,000-ton press that could bend 12” thick steel into a cylinder for a completed nuclear vessel weighing 700 tons.

A gang drill setup to drill 1600 holes through a 26” Inconel tube sheet for nuclear PWR steam generators.

A 1000-ton crane to handle these fabrications and heat treat furnaces large enough to stress relieve them before shipment. What an experience to view and work with these marvels.”

The facility evolved and progressed over many years to become the pearl of manufacturing prowess that it was in 1975. Combustion-Engineering in these times was capable of producing steam generators that could power about 25,000 MW of electricity generation capacity each year. The business volume in 1977 dollars was about $1 billion/year.

The manufacturing volume was almost equal to the business profits of aftermarket maintenance and repairs. Being outstanding in design, manufacturing and services was a huge business for tens of thousands of employees. In 1978, Combustion-Engineering was #125 on the Fortune 500 list of companies. Two competitors during this era with facilities similar to Combustion-Engineering were Babcock & Wilcox and Foster-Wheeler. B&W was # 132 on Fortune’s list and Foster-Wheeler # 207.

Today, Combustion-Engineering and Foster-Wheeler U.S. shops are gone, B&W’s downsized but, thankfully, still in operation.

Recently, I discussed a replacement/repair of a high-pressure header for an existing Utility coal steam generator in Texas. I was told the header is on emergency order and it will be on site this fall. The header is sourced from somewhere in Asia, and welding of tube studs and completion of fabrication will be done in South Carolina. This is about 24 weeks lead time for just one header. I described a 1,350 MW steam generator in a previous article, here, just to show a rough idea of the immensity of a large coal supercritical steam generator. The one described is the B&W Zimmer Plant, a supercritical steam generator.

How About Nuclear Manufacturing in the U.S.?

One of my first positions in the power industry was working at Babcock & Wilcox’s Barberton facilities as a Technical Assistant to the Project Engineer for the design and fabrication of the Duke Power Oconee Nuclear Steam System (NSS). At that time, B&W had over 30,000 employees.

B&W has since been separated into two fine companies B&W and BWXT and are still capable of building both coal and nuclear power generation equipment. However, this manufacturing capacity, as far as I know, is downsized from that in place in the early 1970’s before the Three Mile Island incident. A previous article covers manufacturing in the 1970’s here.

Compare Current U.S. Nuclear Plans with the World

America has more operating nuclear plants than any other country. However, the average age of these is over 40 years. America’s nuclear fleet was built between 1960 and 1990. For NEW Nuclear, here is the chart by the World Nuclear Association:

The chart below is China’s current electricity generation by fuel, according to the EIA. Yes, it is 60% coal, 14% hydro, 18% renewables and 5% nuclear power for electricity generation as of this writing. The fact is, China is continuing to operate old and to also build new coal plants as required to power their economic and industrial growth. Yes, they also are building new renewables and nuclear for a balanced generation portfolio. It is hard to criticize this approach to powering the future. America should do likewise.

Conclusions

President Trump’s Executive Orders, which declared an electricity generation emergency, are, in fact, correct. America does have a crisis of the supply chain to build the new 24/7 electricity generation capacity needed in the future. It will be difficult to build the needed generation capacity due to the hollowing out of the supply chain.

The destruction of reliable coal plants without replacing them in kind has been wrong and reckless. This is the root cause of the electricity generation crisis.

Those policymakers who have engaged in the “War on Coal” are related to or aligned with advocates of Socialism and Communism. The Capital Research Center, General Robert Spaulding, Frank Gaffney, and the Center for Present Danger China, and others have linked foreign entities to the “Red-Green New Deal” that is at the root of the self-sabotage of our reliable forms of electricity generation through China’s “unrestricted warfare”.

The shortages of electricity and resulting rationing (a/k/a Demand Response) will be worse during peak Demand periods, July-August, and December-February

Building 150,000 MW of new electricity generation capacity that is dispatchable by 2030 will be difficult unless all proven 24/7 affordable electricity generation fuels are included, including coal, nuclear, and gas.

The U.S. supply chain for critical manufacturing of steam generators, transformers, pumps, feed water heaters, nuclear reactor pressure vessels, nuclear steam generators, and other equipment has been harmed by U.S. businesses and government outsourcing too much manufacturing to China.

Building the electricity generation capacity needed will require much more training of talent in the workforce because, as the supply chain of U.S. power equipment manufacturing has withered, many of the experienced craft persons and engineers have found other work or retired.

#PowerPlants #Electricity #Coal #Nuclear #ClimateChange #NaturalGas #Rationing #EnergyDemand #ElectricityDemand

Bravo Dick. let's hope (and pray) that the innovators and capital markets are released to do their best work!

Great essay. This is a must read for every green energy activist. It’s so frustrating. In the 80’s I was. BT on a Destroyer it had two CE 1200 psi boilers in each fire room. They were fun to operate. Thanks for a great article, prayers some more people will care to be educated on these issues.