Guest Post by Roger Caiazza of Pragmatic Environmentalist of New York.

This is an article primarily by Richard Ellenbogen that estimates projected annual operating costs and emission reductions for New York commercial facilities when the new building codes are implemented. It is also an example of how peer review should be done.

Ellenbogen is the President [BIO] of Allied Converters and frequently copies me on emails that address various issues associated with the New York Climate Leadership and Community Protection Act (Climate Act). I have published other articles by Ellenbogen including a description of his keynote address to the Business Council of New York 2023 Renewable Energy Conference Energy titled: “Energy on Demand as the Life Blood of Business and Entrepreneurship in the State -video here: Why NY State Must Rethink Its Energy Plan and Ten Suggestions to Help Fix the Problems”. He comes to the table as an engineer who truly cares about the environment and as an early adopter of renewable technologies at both his home and business two decades ago.

Heat Pump Hype

I am a long-time critic of the New York State Energy Research & Development Authority’s (NYDSERDA) biased promotion of all green energy technologies. Their description of cold climate heat pumps is a good example:

“Today’s cold-climate heat pumps are a smarter, more efficient option to keep your home comfortable all year long. These all-in-one heating and air conditioning systems are environmentally friendly, extremely efficient, and affordable to operate.”

In another example, they breathlessly claim that heat pumps outsell gas furnaces for the second straight year. This claim uses national figures and could be solely the result of new building sales that are much stronger in southern states where heat pumps are a cost-effective choice. Ellenbogen addresses the affordability claims below.

Ellenbogen Heat Pump Experience

Ellenbogen installed geothermal heat pumps when his house was completed in 2004. He has 21 years of experience with them and has maintained a database of the performance and costs. His monitoring system includes temperature sensors on the inputs and the outputs of the wells and water flow. Because he uses a geothermal system, he can rely on it even during the coldest periods when air source heat pumps cannot extract enough energy from the air to keep the house warm.

Furthermore, his system uses deeper wells than are currently allowed by law that were legal when the system was developed. They are also open loop which greatly increases their efficiency but that is also no longer allowed. In his configuration, his heat pumps can pull 7 tons of heat transfer per well where current geothermal wells are limited to about 2.5 tons per well.

As a result, his system can achieve a Coefficient of Performance (COP) of about 5.5 whereas current Geo-thermal systems can achieve a COP of about 3.5 with the restrictions on well depth and having to be closed loop. During long periods of cold temperatures that force the heat pumps to run for extended periods, the well temperatures can drop, and the efficiency of the system decreases so it will use more energy.

One of the things I admire, as a techno-weenie, is Ellenbogen’s quantitative nature. He built his house “as a science project to satisfy his intellectual curiosity” and it has yielded an enormous amount of data. When the Indian Point nuclear station was operating, he ran a calculation and found his geothermal system was about 7% more carbon-free than his 95% efficient modulating gas boilers that were originally installed as a backup in case of a power failure.

After New York politicians shut down Indian Point the carbon emissions of local electricity increased, and the GHG emissions advantage vanished. Given his concerns about GHG emissions, he decided to figure out a cost and energy comparison. He turned the heat pumps off this winter and used the duplicate gas system to compare with multiple years of data with the heat pumps operating.

The results are notable. His gas bill went up less than the electric bill went down, and this is for an electric system with an efficiency 57% higher than what can be built now during a colder winter.

The electric bill was about $8,600 lower than it would have been with the heat pumps operating. The gas bill only went up by $6,057 for a net savings of $2543 using the natural gas heating and the current winter has been 120 degree days colder than last year. That figure has been adjusted for the higher electricity prices this year.

Note that the heating system is well-designed with 14,500 square feet of high mass radiant floors that use 100-degree water in the system and 18 separate zones which makes it even more efficient. The large scale of the system removes measurement aberrations that might occur with a smaller system.

To compare the costs of heating with electricity and natural gas it is appropriate to compare the cost to generate the same amount of heat.

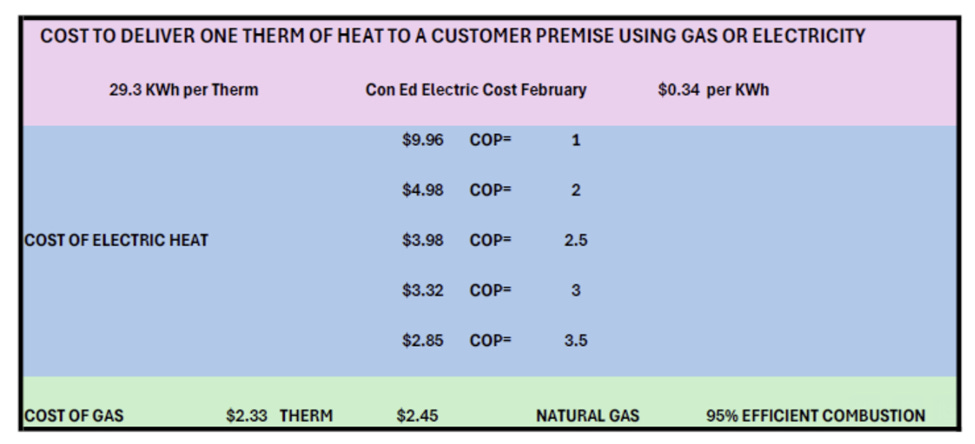

Table 1 lists the cost for the delivery of one therm (heat energy equal to 100,000 British thermal units) between a 95% efficient boiler and electric heat at relationship different Coefficient of Performance efficiency values. A COP of 1 is inefficient. A highly efficient ground source heat pump has a COP of 3.5.

Even an efficient ground source heat pump is 16% more expensive ($2.85 for one therm compared to $2.45 for a 95% efficient gas system in the Downstate New York area which covers 60% of the state’s population. Also note that air source heat pumps on a very cold day can reach COP’s of 1 – 1.5 and easily go below 2. As a result, they can be two to three times as expensive to operate.

Commercial Facility Projection

New York State legislators passed a prohibition on the installation of fossil fuel equipment and building systems starting in 2026 for small buildings and 2029 for larger ones. The prohibition starts in 2026 for new buildings up to 7 stories tall, except for commercial and industrial buildings larger than 100,000 square feet.

There are exemptions for certain types of buildings including emergency backup power systems, manufacturing facilities, commercial food establishments, laboratories, hospitals and medical facilities, critical infrastructure (e.g., water treatment plants), agricultural buildings, and crematoriums.

Ellenbogen applied the numbers derived from his house experiment to his business and extrapolated them to the 55,000 square foot factory which would fall under the less than 100,000 square foot rule for new construction after 2026. Admittedly, there is no law currently in place that would require a developer who wanted to replicate Ellenbogen’s manufacturing facility because of the exemptions.

Eventually, however, the net-zero mandates will require all electric construction of all new facilities and for the replacement of existing equipment before the end of useful life. Therefore, it is a relevant example of Climate Leadership and Community Protection Act (Climate Act) costs.

Ellenbogen’s home has a backup gas boiler heating system, and his manufacturing plant has a combined heat and power system. In 2002, he installed the first microturbine-based Combined Heat and Power (CHP) system in the Con Ed service area. This approach generates electricity by burning natural gas. Waste heat is recovered “to heat the building in the winter, or to be sent to absorption chillers to cool the building in the summer.” This approach allows him to recover 70 to 75 percent of the energy content of the fuel and augments a solar array on the roof.

By doing a thermal analysis of his home’s gas usage he was able to determine what would be needed to heat the factory. The end result is that removing gas from his manufacturing facility would raise energy bills to about $147,000, more than doubling them, and raise his carbon footprint by about 15%. The key takeaway is that even using the most efficient electric heating/cooling system available, it still means that this gas ban policy will cost businesses in NY state enormously while raising carbon emissions. When and if the downstate New York electric system reaches zero GHG emissions, the carbon emissions will be reduced.

Environmental Impacts

Ellenbogen calculated that because the downstate electric system’s CO2 rate is 950 pounds per MWh according to 2022 EPA data, the CO2 emissions from using the CHP system are actually less than if heat pumps were used. He also pointed out he has replaced three compressors in his home’s ground source system over the past 21 years, and each time the failure resulted in a full loss of refrigerant. He said that it is not preventable and that you only find out when the unit gives a fault code with no early warning.

Discussion

This post is based on three emails from Ellenbogen. I did not include all the calculation details he provided in the originals, but will provide them if requested. The reason for the three versions is that the details provided enabled a reader to point out an issue that he corrected. Ellenbogen noted that:

Those damned Laws of Thermodynamics are getting in the way again, but this may be a teaching moment to show what a real peer review looks like and that we have to acknowledge errors to make sure that the best information is in the public space. It also is a clear example of how we can’t escape those laws in our calculations. Miscalculations introduce errors, and a failure to account for the Laws of Thermodynamics entirely when setting energy policy introduces huge errors.

This raises an issue with the implementation of the Climate Act. The agencies responsible for the implementation plans have not provided adequate documentation to enable a detailed review of the plan. Even if it is possible to make a detailed comment on an obvious issue, there hasn’t been any acknowledgement of any problem, much less evidence of a revision to the plans. The appropriate peer review process exemplified by Ellenbogen’s analysis is not a feature of the Climate Act stakeholder process. As a result, Ellenbogen notes “errors are apparent across the entire spectrum of NY State’s Energy plan.”

Ellenbogen summarized his peer review concerns in this regard.

While I hate to beat on academia, it has a great deal of responsibility for NY State’s energy mess. A certain university professor who sat on the Climate Action Council still refuses to acknowledge that all of the technologies for this transition do not exist, despite a Public Service Commission conference determining that fact in 2023. Unfortunately, people in the legislature and certain environmental groups have adopted those ideas despite there being known large deficiencies in those theories as it applies to putting them into practice. Untested theories that can’t be put into practice in the “Real World” are dangerous for society. State residents shouldn’t be turned into a science project and that is what is happening.

I received the following response to my email from a retired professor who now works in industry. I have redacted portions to keep them anonymous. While on average, the refrigerant replacement is every 20 years as there are three heat pumps, their observations are profound and are critical to understanding a huge issue now facing the NY State. It follows in italics.

This is the most sobering analysis of a heating system I have ever read. I constantly hear about the miracles of heat pumps, but the carbon footprint is never honestly presented. Plus, the replacement of freon every 7 years is never included. Thanks for providing a clear analysis of a day in the life of a NY business and resident.

I’m still enjoying life in XXXXXXXX, and in no longer being a professor. Academia lives in a bubble, and you can’t see that until you leave. Professors need to do a real sabbatical leave in industry and be forced to solve real problems, not problems they dream up. It’s tough out here! I thought I knew something about XXXXXX after XX years as an academic doing research, but XX years at XXXXXXX has shown me I have much to learn. It is stimulating, I’m glad to be here. They need to have a similar experience.

Regarding the statement above, one of the reasons that the carbon footprints of heat pumps is never honestly mentioned is that the loudest voices in the space are the people selling them and other people don’t have enough experience to question the results. I’ve been using them for 21 years. My house was built as a science project to satisfy my intellectual curiosity. It has yielded an enormous amount of data, some of which has been used by the state.

One of the major issues that I have with NY State policy is that many of the people hired to do the energy analyses for the government work for the manufacturers or other interested parties. The reports read more like advertisements paid for by the NY State taxpayers than a sound scientific document. I dealt with that in a 2020 paper on the Lansing Gas moratorium. The company hired to do the Tompkins County energy analysis sold heat pumps, and the resulting report reflected that and had a huge error in its results. The paper is very relevant to the building electrification discussion.

Regarding the professor’s comments, when someone is forced to deal with the consequences of their decisions as occurs in industry, it greatly changes their perspective. There are no negative consequences for someone theorizing about policy on a University Campus and that is okay because it can move society forward. However, if they don’t test those ideas before pushing them into society as a gospel, there will be huge problems and that is what we are now seeing in NY State.

Conclusion

The ramifications of New York’s Climate Act on business development are becoming evident. In 2026, certain new buildings in New York will no longer be able to install fossil fuel equipment and building systems.

Richard Ellenbogen has performed a “science project” that proves that New York’s net-zero transition electrification plans for heating will be more expensive than using natural gas. It is also notable that the experiment was best on a geothermal heat pump system that is more efficient than legally possible today. Adding to the already large energy costs in New York is not a good way to attract and maintain manufacturing in the state.

This exercise also shows the importance of robust peer review. Ellenbogen’s first draft contained an error that was identified because he showed his work. He acknowledged the problem and corrected his analysis. New York’s Climate Act stakeholder process does not document analyses well enough for considered review and the Hochul Administration does not acknowledge any comments that do not comport with their narrative. As a result, the broken stakeholder process in New York will likely ignore Ellenbogen’s real-world results.

#GHG #Caiazza #Climate #Hochul #NewYork #ClimateAct #Emissions #HeatPumps #Ellenbogen

Roger Caiazza blogs on New York energy and environmental issues at Pragmatic Environmentalist of New York. This post represents his opinion alone and not the opinion of his previous employers or any other company with which he has been associated. Roger has followed the Climate Leadership & Community Protection Act (Climate Act) since it was first proposed, submitted comments on the Climate Act implementation plan, and has written over 500 articles about New York’s net-zero transition.

It’s just so simple — natural gas for space heating. Natural gas for thermal process heat. For electricity generation for a large grid - coal, natural gas, nuclear.

Smart meters create fire hazords theyll reach over 5000 degrees Fahrenheit